Exhaust gas recirculation

The combustion of fuel in the internal combustion engine of a hybrid vehicle produces pollutants. Exhaust gas recirculation is a method of reducing pollutant emissions from an internal combustion engine.

Safety

Faults in the exhaust gas recirculation system (EGR system for short) are shown by the malfunction indicator light. They can be noticed due to jerking, uneven idling or lack of power. Vehicles affected by this type of fault will often switch to emergency operation; this changeover manifests itself to the driver in the form of significantly reduced power. The switch to emergency operation protects the engine against damage.

Function

Exhaust gas recirculation (EGR) is a tried-and-tested method of reducing harmful substances. In this process, a defined quantity of exhaust gas is removed at the exhaust manifold and mixed back in with the intake air. This reduces the amount of oxygen in the fuel/air mixture, thereby reducing the combustion temperature in the cylinders.

As hazardous nitrogen oxides (NOx) are produced primarily at high temperatures and pressures, exhaust gas recirculation provides a means of reducing the levels of NOx concentration emitted to the environment by up to 50%. In diesel engines, exhaust gas recirculation also reduces the formation of soot particles by approx. 10%.

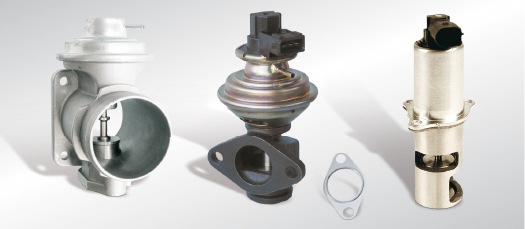

Components

The amount of exhaust gas recirculated is calculated by the engine control unit and regulated depending on the design of the system by means of various actuators. These include the following:

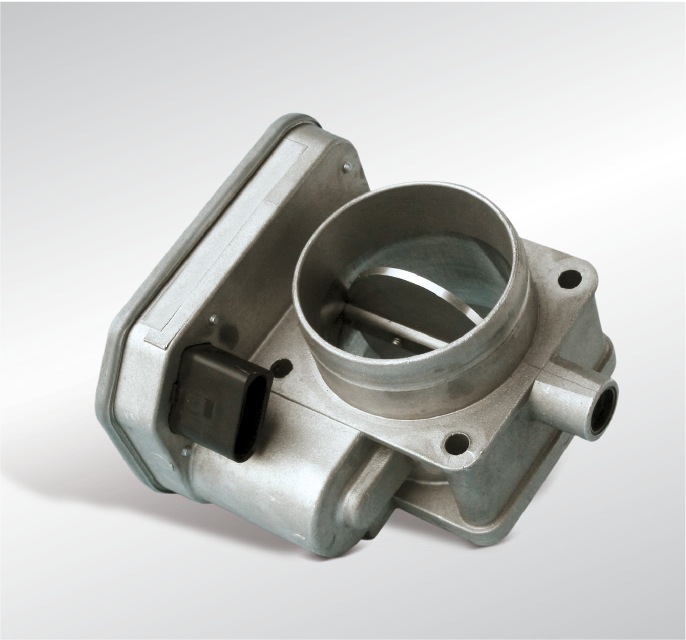

EGR valve

The EGR valve is responsible for dosing the quantity of exhaust gas recirculated. It is mounted either on the exhaust manifold or in the intake area. In some engines, it is located inside a heat-resistant exhaust gas line which connects the exhaust manifold to the intake area

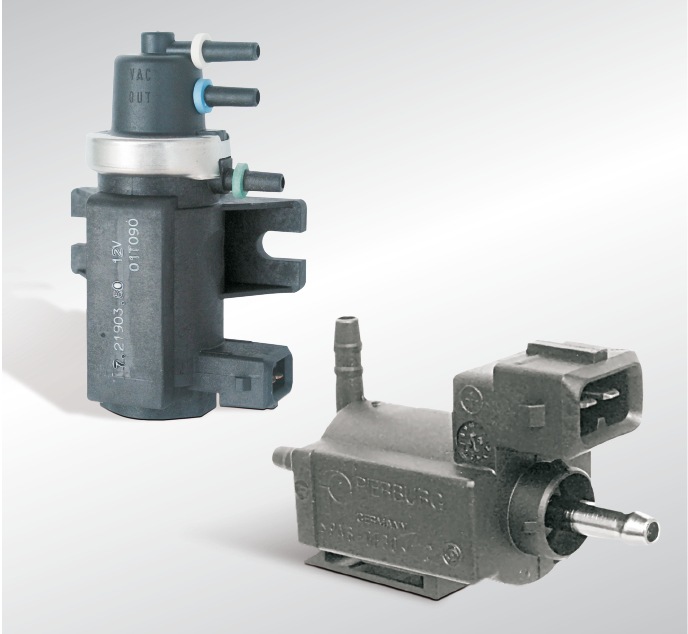

Electric changeover valve

In simple systems with an electric changeover valve, the EGR valve simply has an open/close function. The negative pressure required to control the valve is tapped from the intake pipe or generated with a vacuum pump.

Electropneumatic converter

In systems with electropneumatic converters, the EGR valve is infinitely variable. Here, the negative pressure required to control the valve is tapped from the intake pipe or generated with a vacuum pump.

EGR lines

Flexible or rigid EGR lines are available. They connect all of the components for exhaust gas recirculation: from the exhaust gas extraction point to the intake area, running via the EGR radiator and the EGR valve. As space is at a premium inside the engine compartment, connection routes often have to be complicated.

Modern EGR lines must meet the following high requirements:

- They must compensate for different and changing temperature levels at the mounting points and installation tolerances of the components concerned

- They must be resistant to high temperatures, exhaust gases and corrosion

Environmental protection

Exhaust gas recirculation is one of the most important methods to reduce harmful substances. It helps to reduce the concentration of hazardous nitrogen oxides that are emitted into the environment by up to 50%. With diesel engines, exhaust gas recirculation also reduces the formation of soot particles by approx. ten percent.

Depreciation

The exhaust gas recirculation system does not require any particular care. If the oil change and maintenance intervals are not complied with, this can lead to malfunctions. An exhaust gas recirculation system that is in perfect working order is a prerequisite for passing the exhaust gas test.