Towbars

The purpose of a Towbar is to hook up a trailer to a vehicle.

Function

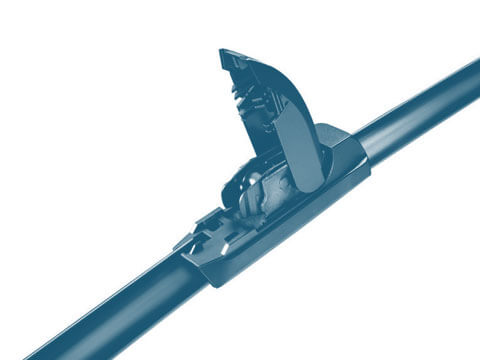

A basic distinction is made between fixed, removable and retractable towbars to suit the requirements of the user.

Fixed towbar

A fixed towbar is usually the least expensive type and is particularly suitable for regular use. It is permanently installed and cannot be removed.

Removable towbar

A removable towbar offers far greater flexibility: After removing the neck there is generally nothing left to be seen of the towbar. Removable towbars are ideal for motorists who only use a towbar occasionally to tow a trailer or for mounting a bike rack.

Retractable towbar

Retractable towbars are convenient and easy to use. The towball stays under the car's bumper until it is needed. It can be swivelled out electrically or manually when required.

Trailer lighting

Regarding the lighting, the same regulations apply to trailers as to all motor vehicles: trailers must have brake lights, tail lights, indicators and two rear fog lights. Reversing lights can be attached.

Electrical connection

The towing vehicle takes over the power supply of the trailer. This is made possible by so-called wiring

kits, which are also known as “trailer sockets”: They establish the electrical connection between the

trailer and the vehicle. There are basically two variants: The 7-pin E-Set and the 13-pin E-Set.

7-pin wiring kit:

The 7-pin wiring kit is typically used for small cargo trailers. It is not possible to connect the reversing

light.

13-pin wiring kit:

The 13-pin wiring kit has been standard since the late 1980's. With the 13-pin e-set, reversing lights, continuous current and charging cable can be used on the trailer. This connector is particularly suitable for caravans, cycle racks and horse trailers. The 13-pin electrical kit is already required for many new trailers.

Leading manufacturers offer a wide range of wiring kits, ranging from wiring kits with relay technology to state-of-the-art CAN bus kits that are actively connected to the vehicle data bus. New functionalities, such as driving stabilization when towing a trailer, can be implemented with vehicle-specific electrical kits.

Elektrische Verbindung

Das Zugfahrzeug übernimmt die Stromversorgung des Anhängers. Möglich machen das sogenannte Elektrosätze, die auch als „Anhängersteckdosen“ bezeichnet werden: Sie stellen die elektrische Verbindung zwischen Anhänger und Fahrzeug her. Grundsätzlich werden dabei zwei Varianten unterschieden: Der 7-polige E-Satz und der 13-polige E-Satz.

7-poliger Elektrosatz:

Der 7-polige Elektrosatz wird in der Regel für kleine Lastenanhänger verwendet. Das Anschließen des Rückfahrscheinwerfers ist dabei nicht möglich.

13-poliger Elektrosatz:

Die 13-polige Elektrosatz ist seit den späten 1980er Jahren Standard. Beim 13-poligen E-Satz können Rückfahrscheinwerfer, Dauerstrom und Ladeleitung am Anhänger genutzt werden. Diese Steckverbindung ist besonders geeignet für Wohnanhänger, Fahrradträger als auch Pferdeanhänger. Der 13-polige E-Satz ist bei vielen neuen Anhängern bereits erforderlich.

Führende Hersteller bieten ein breites Elektrosatz-Sortiment an, das von Elektrosätzen mit Relaistechnik bis zu hochmodernen CAN-Bus-Sätzen reicht, die aktiv an den Fahrzeug-Datenbus angebunden sind. Mit fahrzeugspezifischen Elektrosätzen sind neue Funktionalitäten, wie etwa die Fahrstabilisierung beim Anhängerbetrieb, realisierbar.

Safety

A towbar can be retrofitted at any time if a vehicle is licensed for use with a trailer. The permissible trailer loads for a given vehicle (the load which a vehicle is allowed to tow with a trailer) are indicated in the registration documents (braked trailer load: Field O1, unbraked trailer load Field O2). Extra information specifically for the vehicle concerned is contained in the space for remarks. If no trailer load is given for a vehicle, this means the vehicle is not approved for towing a trailer! Manufacturers of towbars have no influence on the information contained in the registration documents. Exceeding the trailer load or using a towbar in a manner contrary to the specifications constitutes a major safety hazard.

Value retention

A towbar is a robust steel component but nevertheless requires regular upkeep, inspection and maintenance.

Signs of damage or severe corrosion may mean that a towbar is no longer roadworthy.

Regular inspection is particularly important if a vehicle comes into contact with salt, as this is extremely aggressive. Without regular care, salt may seriously weaken parts of the towbar and lead to failure of the towbar.

To ensure proper operation, the neck of a removable towbar and the receiver tube must always be kept clean. Regular maintenance of the mechanism is therefore imperative. The lock should only be treated with graphite. It is also a good idea to regularly apply resin-free grease or oil to the bearing surfaces, sliding surfaces and balls. This additionally provides extra corrosion protection.

When cleaning a vehicle with a steam cleaner the neck must be removed and the plug insert fitted. If grease is applied to the inside of the receiver tube before fitting, the plug insert will be "sucked in" and will then remain firmly in position. The actual neck should never be treated with a steam cleaner.

IMPORTANT: The ball mount should be greased before hooking up a trailer. The grease or oil must however always be removed from the ball mount before fitting a bike rack on the towbar! The ball should be protected with a cover when the towbar is not in use.

Removable necks should only ever be repaired and dismantled by the applicable manufacturer. It is advisable to replace extremely worn or corroded necks. If the diameter of the ball mount is less than the legally prescribed minimum of 49 mm at any point, the mount must be replaced.

It is generally not advisable to purchase a used twobar as there is no way of knowing how it has been treated in the past and what condition it is in. Second-hand towbars often have worn elements and come without any fitting instructions.

At worst, the towbar may have suffered accident damage in the past. Hairline cracks or fractures can often not be detected "with the naked eye".