Gearbox

The gearbox is just as important a part of the vehicle power train as the engine. It transmits the engine torque to the wheels and also provides various transmission ratios to enable the speed of the engine to be adapted to different driving situations.

Function

Gearboxes convert the engine torque into the wheel traction required to overcome the motion resistance. As engines only operate in a narrow speed range, gearboxes transform this into the wheel speeds needed for normal operation. In conjunction with a clutch, gearboxes also ensure comfortable starting.

Types of transmission

A basic distinction is made between manual and automatic transmission.

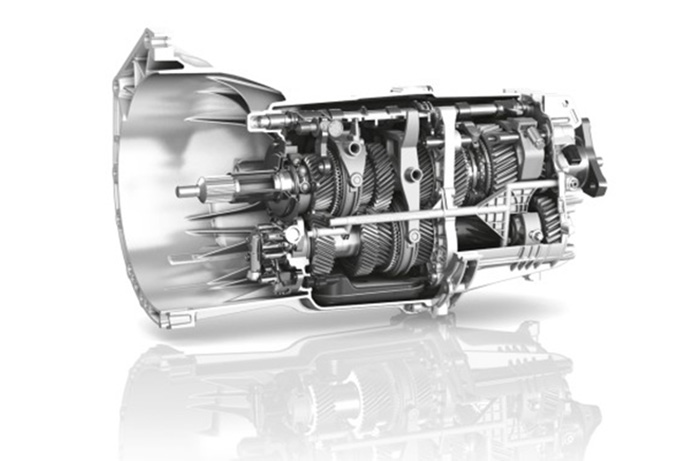

Manual transmission

Manual transmission systems employ the following components to transmit the torque to the wheels:- Starting and separating clutch

- Synchromesh multi-step gearbox

- Shift mechanism for transmitting the gearshift motion from the gear lever to the gearbox

In manual gearboxes the speed of the engine is introduced by way of the input shaft. The output speed, i.e. the speed leaving the gearbox, is the product of various transmission ratios arising from the different speeds of the meshed gears.

Manual gearboxes normally have one gearwheel pair for each speed, with the gearwheels being constantly meshed. However, only one gearwheel of these gearwheel pairs is ever fixed to its shaft. These gearwheels are referred to as speed gears. The gearwheels opposite to these free-wheel on their shaft when not engaged. When a gear is engaged, one of the gearwheel pairs is switched to power transmission. For this purpose, a sliding collar actuated by the gear lever locks the free-wheeling gearwheel to its shaft.

In manual gearboxes the speed of the engine is introduced by way of the input shaft. The output speed, i.e. the speed leaving the gearbox, is the product of various transmission ratios arising from the different speeds of the meshed gears.

Manual gearboxes normally have one gearwheel pair for each speed, with the gearwheels being constantly meshed. However, only one gearwheel of these gearwheel pairs is ever fixed to its shaft. These gearwheels are referred to as speed gears. The gearwheels opposite to these free-wheel on their shaft when not engaged. When a gear is engaged, one of the gearwheel pairs is switched to power transmission. For this purpose, a sliding collar actuated by the gear lever locks the free-wheeling gearwheel to its shaft.

Automatic transmission

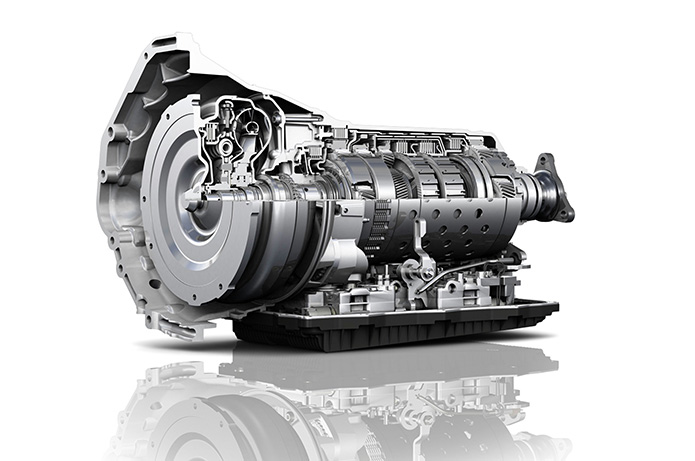

In contrast to a manual gearbox, the following components are used for torque transmission in an automatic gearbox:- Hydrodynamic torque converter

- Selector elements for transmitting the torque on changing gear

- Planetary gearbox with planetary gear sets to provide the different speeds

- Mechatronic module

- Oil pump (vane pump)

- Parking lock

- Selector lever

Instead of a separating clutch, automatic gearboxes are provided with a so-called hydrodynamic torque converter for starting. The engine does not have to be disconnected from the gearbox, as automatic gearboxes are shifted under load and thus transmit the engine torque even during gear change.

Whereas manual gearboxes use a clutch and non-power shift (the clutch disconnects the engine from the gearbox), automatic gearboxes employ power shift. This is implemented by selector elements which use oil pressure (oil pump) to automatically adjust the engine speed to the new gear selected (no disconnection of the engine from the gearbox). The driver does not have to take his foot off the accelerator. All five selector elements of the latest 8-speed gearbox take the form of multi-plate clutches and multi-plate brakes.

In an automatic gearbox the various speeds are provided by the planetary gearbox with its different planetary gear sets permitting reduction or step-up ratios. Several forward gears and one reverse gear can be obtained by linking several planetary gear sets.

In an automatic gearbox the electronic hydraulic transmission control takes the form of a mechatronic module. This is the "heart" of the gearbox where shift programs, adaptation of the shift pressure to the engine torque and safeguarding functions are implemented by the electronics.

Finally, unlike manual gearboxes, automatic gearboxes are provided with a parking lock. This is a locking mechanism for the gearbox output shaft which is engaged in selector lever position P to stop the vehicle rolling away in all situations.

Instead of a separating clutch, automatic gearboxes are provided with a so-called hydrodynamic torque converter for starting. The engine does not have to be disconnected from the gearbox, as automatic gearboxes are shifted under load and thus transmit the engine torque even during gear change.

Whereas manual gearboxes use a clutch and non-power shift (the clutch disconnects the engine from the gearbox), automatic gearboxes employ power shift. This is implemented by selector elements which use oil pressure (oil pump) to automatically adjust the engine speed to the new gear selected (no disconnection of the engine from the gearbox). The driver does not have to take his foot off the accelerator. All five selector elements of the latest 8-speed gearbox take the form of multi-plate clutches and multi-plate brakes.

In an automatic gearbox the various speeds are provided by the planetary gearbox with its different planetary gear sets permitting reduction or step-up ratios. Several forward gears and one reverse gear can be obtained by linking several planetary gear sets.

In an automatic gearbox the electronic hydraulic transmission control takes the form of a mechatronic module. This is the "heart" of the gearbox where shift programs, adaptation of the shift pressure to the engine torque and safeguarding functions are implemented by the electronics.

Finally, unlike manual gearboxes, automatic gearboxes are provided with a parking lock. This is a locking mechanism for the gearbox output shaft which is engaged in selector lever position P to stop the vehicle rolling away in all situations.

Safety

The parking lock of an automatic gearbox stops a stationary vehicle rolling away. The electronic hydraulic transmission control prevents impermissible gearshift operations by the driver and thus protects the gearbox against damage resulting from incorrect use.

Value retention

The fact that automatic gearboxes are becoming ever more popular on account of the advantages they offer (relaxed efficient driving) means that they can make a significant contribution to value retention. Furthermore, luxury class vehicles are often expected to have an automatic gearbox, which again makes it a value retention factor.

Protection of the environment

Reducing the drag torque in the gearbox (optimised plate configuration, oil pump optimised in terms of size and volumetric flow, demand-based lubricant control) made it possible to reduce fuel consumption. Modern automatic gearboxes use up to 6 per cent less fuel than manual gearboxes. Further savings can be achieved in combination with stop-start systems and the use of new technologies such as hybrid transmission.