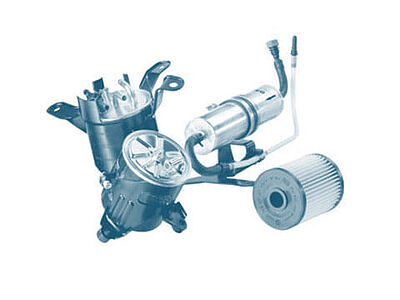

Fuel filters

Although high standards of fuel quality can now be taken as read in western Europe, there is still a risk of dirt particles and water getting into fuel tanks. However, fuel injection systems for modern engines...

Function

Although high standards of fuel quality can now be taken as read in western Europe, there is still a risk of dirt particles and water getting into fuel tanks. However, fuel injection systems for modern engines and the carburettors in order cars need fuel that is absolutely clean if they are to be relied up on to function effectively. Dirt particles cause wear and block the bore holes in fuel preparation systems, some of which are very small. Water in the injection system can cause corrosion and also lead to the failure of components, resulting in engine standstill.

It is for this reason that every combustion engine is fitted with a fuel filter. The fuel filter must filter dirt particles out of the fuel (some fuel filters are designed to also filter out water). In so doing, it makes an important contribution to the operational reliability of the engine.

Design

Fuel filters are available in a variety of designs.

Fuel filter elements:

They can be replaced and are located in a separate housing integrated in the engine.

Spin-on filters:

They form a single unit comprising housing and filter element and are replaced as a single unit during service and maintenance. Depending on the application, these designs will feature additional functions such as a water drain plug and connecting branches for a fuel heating unit and the water level indicator.

Inline fuel filters:

These filters are installed in the fuel line. The housing and the filter element form a single unit which is replaced during service and maintenance. Inline fuel filters can be made from steel, aluminium and plastic according to manufacturer requirements.

Anforderungen an Kraftstofffilter

The fuel filters in modern injection systems must meet very exacting requirements. Fuel filters for common rail or pump-nozzle diesel injection systems must provide an assurance of particularly high levels of fuel cleanliness, for example. As a consequence of the high injection pressures (up to 2000 bar and in some cases even higher), the injection system components have very low tolerances. Even the tiniest dirt particles can cause these systems to malfunction or even fail completely. Innovative filter systems that are able to meet these requirements are the order of the day.

The filter media must also be resistant to modern fuels (which contain high levels of ethanol or biodiesel, etc.) and provide an assurance that flow rates and filter performance will remain at consistently high levels across a wide temperature range (between -40 °C and 100 °C). Furthermore, fuel filters must be able to tolerate mechanical loads, in particular if they are mounted on vehicle underbodies.

Safety

Well-known component manufacturers are developing high-performance filter media equivalent to the original equipment quality achieved by leading vehicle manufacturers. Every fuel filter is developed to meet the precise requirements of the prevailing application. As such, branded filters are able to meet the exacting requirements set by manufacturers of injection systems and protect both the injection system and the engine. As a result, they safeguard the reliable operation of the vehicle even in difficult operating conditions.

Another important aspect in fuel filter development is crash safety. The filter elements must be designed and built as appropriate for the installation location so that there is no risk of the filter bursting and fuel escaping in the event of an accident. Frost-proof valve design and additional functions such as heating and water drain equipment complete the contribution of fuel filters to the reliable operation of the vehicle.

Environmental protection

Brand manufacturers produce fuel filters in compliance with the most stringent of environmental guidelines. Following replacement, recycling is assured by a universal take-back system. From the point of view of the environment, metal-free filter elements (used in fuel filter modules) are the better choice. Ultimately, the reduction in the use of raw materials in production, less waste as a result of service and maintenance work and fewer problems with disposal result in a comparable reduction in impact on the environment.

Depreciation

The fuel filter is a typical wear part. It becomes increasingly clogged over time, hindering fuel flow. This can impair both engine performance and smooth running. Therefore, fuel filters must be replaced at regular intervals (usually after approx. 60,000 km). This work is carried out during regular inspections at prescribed intervals.

Only branded filters in original equipment quality should be used when replacing fuel filters. Using non-named products risks poor filter performance. This can result in

- wear to the components of the injection system,

- loss of engine power,

- significantly higher fuel consumption and

- expensive repair work.

A fuel filter in original equipment quality, on the other hand, will safeguard engine performance and help the vehicle to retain value.

Downloads

Here you can find all available downloads for the topic "Fuel filters":

All file downloads: