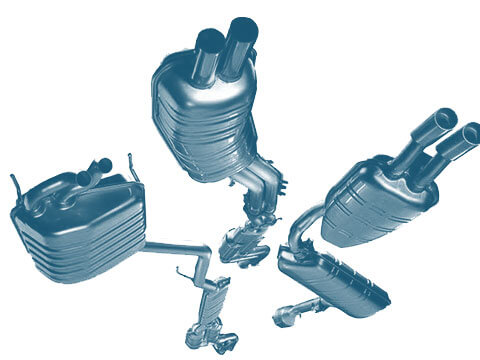

Exhaust manifold

The exhaust manifold is tasked with collecting the exhaust fumes generated by an internal combustion engine and conveying them towards the catalytic converter or turbocharger. The name refers to the assorted inlets and outlets present on the manifold, which guide the exhaust fumes emitted from the cylinder head towards the underbody.

Function

As the first component in the exhaust system, the exhaust manifold collects the exhaust fumes released from the engine cylinders and directs them to the catalytic converter. In turbocharged engines, the turbocharger is situated downstream of the exhaust manifold.

The design of the exhaust manifold has a significant influence on the performance and torque characteristics of an engine, as does the design of the connected pipes.

The fact that the individual exhaust tracts are merged into one ensures that pulsations, i.e. fluctuating pressure surges given off by a certain cylinder, do not prevent exhaust fumes being released from another cylinder. What’s more, waves of negative pressure are intended to promote the flow of exhaust fumes out of the cylinders.

Exhaust manifolds are often made of alloyed cast iron, which is able to withstand the high exhaust temperatures. Alternatively, exhaust manifolds made of stainless steel are also used.

Safety

Exhaust manifolds are subject to high thermal stress because they are the first component to convey exhaust fumes away from the engine. The significant expansions caused by temperature combine with the associated cyclical tension resulting from repeated heating and cooling to subject the material to fatigue. In turn, this can eventually cause the component to fail. Vibrations cause additional stress. Cracks in components let hot exhaust fumes enter the engine compartment and cause additional, unwanted noise. The materials and designs employed today generally enable the manifold to last for the entire service life of the car.

Protection of the environment

To ensure low pollutant emissions, it is important for the catalytic converter to reach its operating temperature quickly. The thermal capacity of the exhaust manifold plays an important part in this. To put things simply: the less mass a manifold has, the more heat is available to the catalytic converter in the start phase.

Value retention

Exhaust manifolds should be installed according to the vehicle manufacturer’s specifications. Likewise, when replacing the manifold, new gaskets must be used to ensure that exhaust fumes do not leak from the components. It is also important for the downstream components to be in a satisfactory condition, and for them to have been installed and secured correctly. Additional stresses caused by catalytic converters that have been installed twisted, for example, are also to be avoided.