Secondary air system

In petrol engine vehicles, secondary air injection is a proven method of reducing harmful substance emissions during cold starting. A petrol engine needs a "rich mixture" for reliable cold starting...

Depreciation

The secondary air system is a maintenance-free vehicle system. However, exceeding maintenance intervals, extreme operating conditions, damage to mixture preparation or ignition and the use of poor-quality engine oils and fuels can lead to soiling and sticking of secondary air valves. A secondary air system that is in perfect working order is a prerequisite for passing the exhaust gas test carried out as part of the roadworthiness test.

Safety

Faults in the secondary air system often manifest themselves in the form of oscillating idling speed or a whistling noise during cold starting. They are signalled by the engine indicator lamp lighting up. The vehicle will often switch to emergency operation (reduced performance). Only a garage can rectify faults affecting a secondary air system.

Function

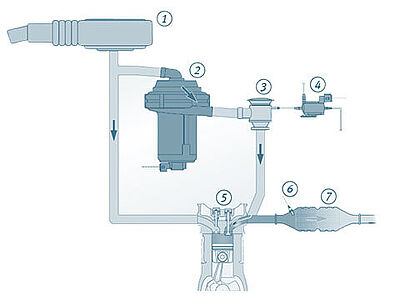

In petrol engine vehicles, secondary air injection is a proven method of reducing harmful substance emissions during cold starting. A petrol engine needs a "rich mixture" for reliable cold starting. This means that the fuel/air mixture contains excess fuel. As a result, high quantities of carbon monoxide and unburned hydrocarbons are produced during cold starting. Since the oxygen sensor emissions control and the catalytic converter have not yet reached their operating temperature at the time of this phase, these harmful exhaust gas components can escape into the environment if not re-treated.

To avoid this and reduce harmful substances during cold starting, ambient air containing high levels of oxygen ("secondary air") is injected into the exhaust gas manifold directly downstream of the exhaust valves using the secondary air system. This causes post-oxidation ("post-combustion") of the harmful substances, creating harmless carbon dioxide and water. The heat generated as a result of this process also heats the catalytic converter and reduces the time taken for the oxygen sensor emissions control to commence operation. The secondary air system comprises the secondary air pump and the secondary air valves.

Environmental protection

Secondary air injection is the most important method of reducing the high concentrations of carbon monoxide and unburned hydrocarbons during cold starting. As such it makes an essential contribution to minimising harmful substance emissions in this phase and ensuring compliance with current emissions standards.

Downloads

Here you can find all available downloads for the topic "Secondary air system":

All file downloads: