Drum brake

Drum brakes may date back almost as far as cars themselves, but they are still installed in some electric and hybrid vehicles today. Together with the disc brake, they are a type of friction brake and supplement the regenerative brake system with recuperation function in many brake systems.

Function

The conventional friction brake remains indispensable, even in hybrid and electric vehicles that have a regenerative brake system, because the braking power generated during recuperation is not sufficient for all the vehicle’s braking needs. For this reason, disc brakes and to some extent also drum brakes also continue to be used in electric vehicles.

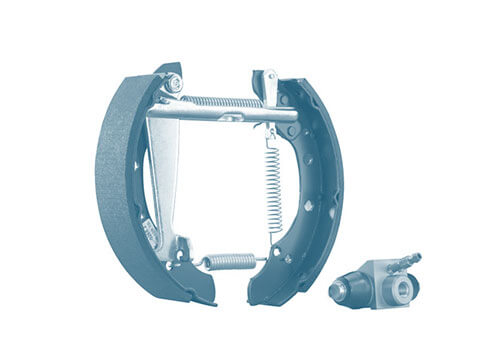

Drum brake components

The term “drum brake” describes the design principle: namely, an enclosed cylindrical structure. A drum brake comprises the following components:

- Brake drum

- Brake shoes

- Wheel cylinder

- Anchor plate

- Adjuster

- Return springs

- Fastening and actuating elements

The brake drum is fixed to the wheel and turns with it. On braking, the wheel cylinder forces the two fixed brake shoes apart and presses them against the friction surface of the brake drum, thus slowing it down. When the brake is released, the return springs pull the brake shoes inwards back to their original position.

Advantages of a drum brake

Drum brakes produce barely any particle emissions and are fully enclosed by a housing. Thanks to this enclosed design, brake dust accumulates inside the drum brake, meaning it can be collected. Moreover, the mechanical components and the brake surfaces inside are well protected against corrosive influences such as rain and salt. The brake shoes are also reliably released from the drum’s surface by spring force, meaning drum brakes are not affected by residual braking torque.

Disadvantages of a drum brake

Like most technical developments, drum brakes also have certain disadvantages. Drum brakes can only withstand low thermal loads and are extremely sensitive to variations in the coefficient of friction. They are thus only suitable for use at the rear axle of low-power/low-weight vehicles. The braking power can also deteriorate at high temperatures (fading). In addition, replacing the lining and drum is a time-consuming business.

Safety

Together with the disc brake, in some hybrid and electric vehicles the drum brake supplements the regenerative brake system with recuperation function, thereby improving the vehicle’s overall braking power. For this reason, the drum brake is one of the most important vehicle systems when it comes to safety.

Drum brakes are relatively low-wear and have a long service life. A specialist workshop should be consulted immediately if deterioration in the braking action of a drum brake becomes noticeable. Drum brakes must only be replaced by qualified personnel. The manufacturer's installation instructions must be observed when doing so.

Value retention

Motorists need not concern themselves with the maintenance of drum brakes. Workshops check the level of wear and the action of drum brakes as part of vehicle inspection. The following aspects must be heeded to ensure optimum braking action and vehicle value retention:

- Only top-quality replacement parts should be used if individual components have to be renewed.

- Replacement parts must be expertly fitted at all times.