Spark plug

If we consider the basic construction of the spark plug, there have been no profound changes over the past 50 years. As ever, the spark plug comprises a metal core which is housed in a ceramic insulator...

Function

The spark plug plays an important role in petrol engines. It is responsible for igniting the fuel/air mixture. The quality of this ignition influences several factors which are of great importance for both driving and the environment. They include smooth running, engine performance and efficiency as well as pollutant emissions.

If we consider that a spark plug must ignite between 500 and 3,500 times per minute, it becomes clear how great the contribution of modern spark plug technology is to adherence to current emissions standards and the reduction of fuel consumption.

The spark plug plays an important role in petrol engines. It is responsible for igniting the fuel/air mixture. The quality of this ignition influences several factors which are of great importance for both driving and the environment. They include smooth running, engine performance and efficiency as well as pollutant emissions.

If we consider that a spark plug must ignite between 500 and 3,500 times per minute, it becomes clear how great the contribution of modern spark plug technology is to adherence to current emissions standards and the reduction of fuel consumption.

Inflammation (ignition)

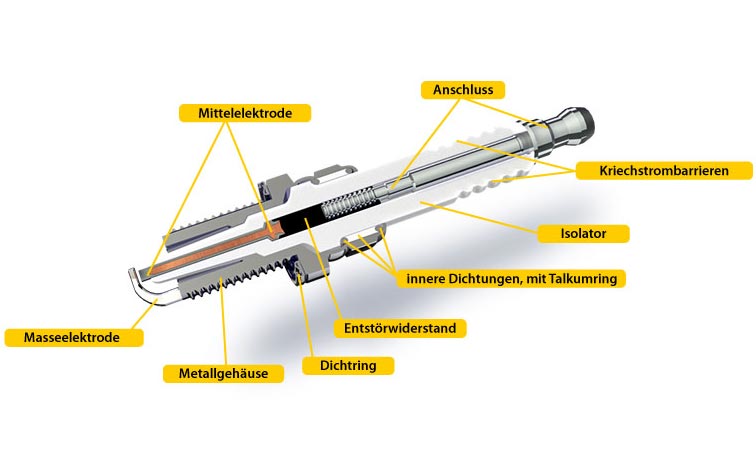

If we consider the basic construction of the spark plug, there have been no profound changes over the past 50 years. As ever, the spark plug comprises a metal core which is housed in a ceramic insulator. This, in turn, is surrounded by a metal casing which has a thread that is screwed in to the cylinder head and normally has a hexagonal section on the top which accommodates the spark plug socket and allows spark plugs to be installed or removed with a spark plug spanner. The main purpose of the construction lies in ensuring that the electrical circuit at high voltage on the spark plug is closed with a spark, which jumps from the middle electrode to the earth electrode.

Connection

The connection is designed as an SAE connection or a 4 mm thread. The ignition cableor a rod coil is plugged into the connection. In both cases a high voltage coupled here must be transported to the other end of the spark plug. The ceramic insulator has two tasks. Its primary purpose is insulation, whereby it prevents flashover of the high voltage to the vehicle mass (= minus), and conducts combustion heat to the cylinder head. The wave-shaped leakage current barriers on the outside of the insulator prevent voltage leaking to the vehicle mass. In doing so, they extend the path to be travelled and increase the electrical resistance, thereby ensuring that the energy takes the path of least resistance - the path through the middle electrode. In order to ensure the electromagnetic compatibility (EMC) and thus the fault-free operation of the on-board electronics, a glass melt is used inside the spark plug as interference suppression. The middle electrode of a standard spark plug is comprised mostly of a nickel alloy. The spark must jump from the end of this electrode over to the earth electrode. The metal housing is firmly attached to the cylinder head via a thread and thus plays an important role in heat dissipation, discharging the bulk of the heat generated during combustion via this connection. The seal ring prevents combustion gas from emerging past the spark plug even at high combustion pressures. In so doing, it prevents pressure losses. Moreover, it conducts heat to the cylinder head and evens out the different expansion properties of the cylinder head and spark plug housing. The inner seals create a gas-tight connection between the insulator and the metal housing, providing an assurance of optimum sealing. The earth electrode of a standard spark plug is made of a nickel alloy. It represents the opposite pole of the middle electrode in normal function.

Temperature and heat flow

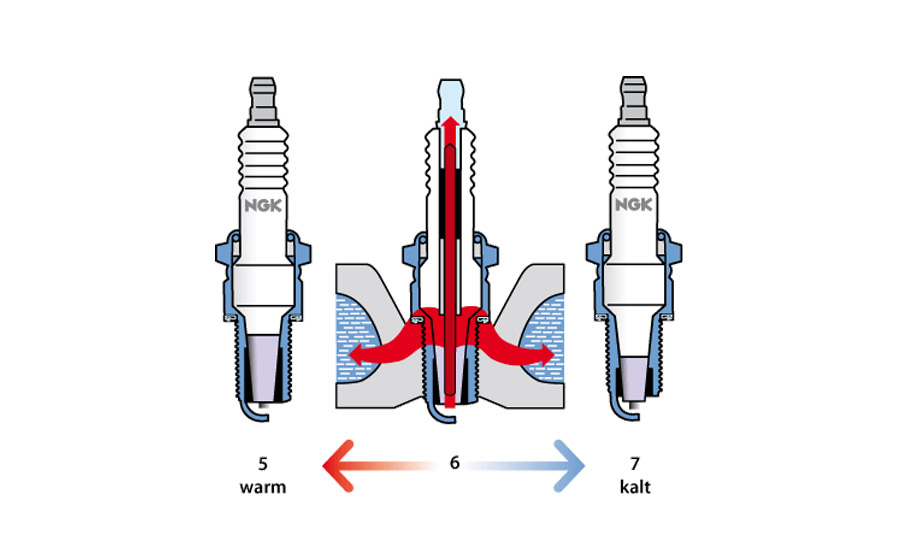

An up-to-date spark plug must be tailored individually to meet the requirements of different engine designs and driving conditions. Therefore, there cannot be one spark plug which will function without any difficulty in all engines. Due to the variations in temperature development in the respective combustion chambers in different engines, spark plugs with different heat ratings are needed. This heat rating is expressed using what is known as the heat rating number. These heat ratings represent an average temperature measured at electrodes and insulators, corresponding to the engine load in each case.

Spark plugs require a special temperature window in order to perform at their best. The lower threshold of this window is a spark plug temperature of 450°C, known as the self-cleaning temperature. Starting from this temperature threshold, the carbon particles which have collected on the insulator tip are burned off.

An up-to-date spark plug must be tailored individually to meet the requirements of different engine designs and driving conditions. Therefore, there cannot be one spark plug which will function without any difficulty in all engines. Due to the variations in temperature development in the respective combustion chambers in different engines, spark plugs with different heat ratings are needed. This heat rating is expressed using what is known as the heat rating number. These heat ratings represent an average temperature measured at electrodes and insulators, corresponding to the engine load in each case.

Spark plugs require a special temperature window in order to perform at their best. The lower threshold of this window is a spark plug temperature of 450°C, known as the self-cleaning temperature. Starting from this temperature threshold, the carbon particles which have collected on the insulator tip are burned off.

If the operating temperature continuously lies below this point, electrically conductive carbon particles can collect, forming deposits until the ignition voltage flows over the carbon layer to the vehicle mass instead of forming a spark. At a spark plug temperature of 850°C or higher, the insulator heats up so much that uncontrolled ignitions can occur on its surface known as glow ignitions. Such uncontrolled, abnormal combustion can lead to engine damage.

If the operating temperature continuously lies below this point, electrically conductive carbon particles can collect, forming deposits until the ignition voltage flows over the carbon layer to the vehicle mass instead of forming a spark. At a spark plug temperature of 850°C or higher, the insulator heats up so much that uncontrolled ignitions can occur on its surface known as glow ignitions. Such uncontrolled, abnormal combustion can lead to engine damage.

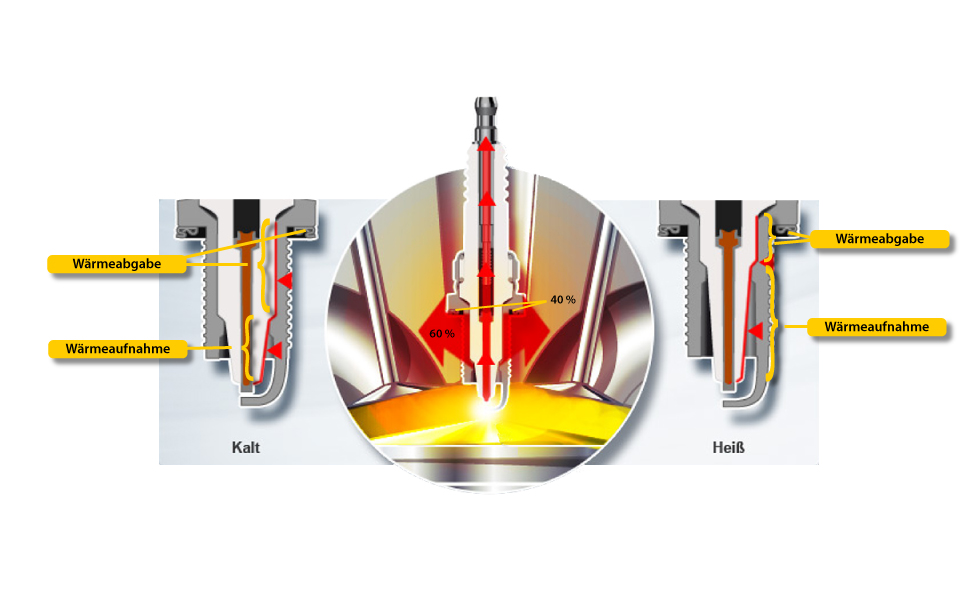

Heat dissipation

Heat development varies greatly from engine to engine. For example, turbocharged engines run significantly hotter than engines which are not charged. Therefore, there is a spark plug for each engine which can conduct a precisely defined measure of heat to the cylinder head and ensures that the optimal temperature window is maintained. The heat rating provides information about the thermal endurance of a spark plug. Every spark plug manufacturer has its own way of expressing the heat rating.

Nearly 60% of the heat is dissipated via the spark plug case and thread. The seal ring conducts slightly less than 40% to the cylinder head.

The small remaining percentage (making up 100%) flows out through the middle electrode. The insulator absorbs the heat in the combustion chamber and conducts it to the interior of the spark plug. Anywhere that it comes into contact with the case, heat is conducted. By increasing or decreasing the size of this contact surface area, it is possible to determine whether the spark plug is conducting more or less heat through the case. The contact surface area is larger for spark plugs with higher thermal endurance. For spark plugs with lower thermal endurance it is smaller.

Heat development varies greatly from engine to engine. For example, turbocharged engines run significantly hotter than engines which are not charged. Therefore, there is a spark plug for each engine which can conduct a precisely defined measure of heat to the cylinder head and ensures that the optimal temperature window is maintained. The heat rating provides information about the thermal endurance of a spark plug. Every spark plug manufacturer has its own way of expressing the heat rating.

Nearly 60% of the heat is dissipated via the spark plug case and thread. The seal ring conducts slightly less than 40% to the cylinder head.

The small remaining percentage (making up 100%) flows out through the middle electrode. The insulator absorbs the heat in the combustion chamber and conducts it to the interior of the spark plug. Anywhere that it comes into contact with the case, heat is conducted. By increasing or decreasing the size of this contact surface area, it is possible to determine whether the spark plug is conducting more or less heat through the case. The contact surface area is larger for spark plugs with higher thermal endurance. For spark plugs with lower thermal endurance it is smaller.

Environmental protection

Today more than ever before, the protection of the environment is the focus of attention where motoring matters are concerned. Particular attention is being paid to exhaust gases. Standard spark plugs in particular are subject to normal wear. When it jumps from the earth electrode to the middle electrode of the spark plug, every spark removes microscopically tiny particles from the electrodes. As a consequence, the distance between the electrodes gets bigger over many thousands of kilometres travelled and the risk of misfiring increases. Every time a spark plug misfires, valuable petrol is injected but not combusted. As a result, there is a significant increase in environmental pollution due to the increased in consumption per kilometre alone. Furthermore, the unburned fuel in the catalytic converter can ignite explosively, causing damage that will prevent the catalytic converter from rendering hazardous substances like carbon monoxide, nitrogen oxide and hydrocarbons harmless and requiring it to be replaced.

Depreciation

A vehicle is a highly complex technical commodity whose function can only be sustained if all components are in perfect harmony. Regular service is necessary if this state of harmony also is to be maintained for the engine, which is one of the most highly challenged parts of a vehicle. This includes using high-quality spark plugs whose technical properties help the drive to function without problems and thus provide an assurance of long service life.

Safety

Spark plugs that are in perfect working order are essential if a vehicle is to operate safely. Spark plugs should therefore be replaced no later than at the end of the replacement interval prescribed by the motor manufacturer. Important: Spark plugs require a precisely measured torque for installation. This necessitates the use of a special tool known as a torque wrench. If the spark plug is not tight enough, pressure will escape from the piston and the spark plug may overheat. There is also a risk that the ceramic spark plug insulator will fracture. This can damage the piston and thus result in engine damage. Conversely, if the torque is set too high, the spark plug might tear off, possibly leading to the cylinder head having to be replaced. Even if this does not happen, a spark plug that has been screwed too tight can overheat during operation, resulting in damage to the engine.