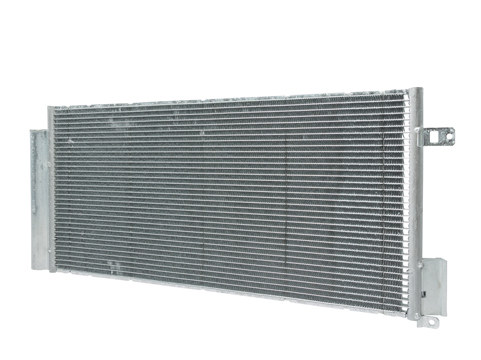

Condenser

The condenser is part of the air-conditioning system and plays a very important role. The function of the air-conditioning condenser is to rapidly cool down the hot refrigerant in the air-conditioning refrigerant circuit.

Function

The primary function of a vehicle air-conditioning system is to cool the interior air. As part of the air-conditioning system, the condenser is a heat exchanger that is normally located in the engine compartment at the front of the vehicle. Its function is to condense the hot refrigerant that comes from the compressor at high pressure. The refrigerant is so hot that it is in gaseous form. It flows through the condenser, where it is cooled down and condensed by the air stream that is also flowing through the condenser. This change of state of the gaseous to liquid state of matter is referred to as the condensation process.

The heat from the refrigerant is dissipated by the condenser fins and tubes. The basic construction of a condenser is similar to that of a coolant cooler for the engine. However, it has to be able to withstand the higher internal pressures that are typical of air-conditioning systems.

Value retention

Continuous high pressure

The more effectively the hot, gaseous refrigerant is cooled down in the condenser, the more liquid is produced. As liquids have a smaller volume than gases, the pressure in the air-conditioning system is reduced. This protects the compressor. The lower the high pressure in the system, the lower the strain on the compressor and the lower the amount of wear. Particularly in summer with consistently high temperatures, the lower cooling of the refrigerant can lead to a continuously higher pressure and thus to a constantly high strain on the compressor. If this is added to the condenser soiling that develops slowly over the years, or if external influences such as insects or stones also cause deformation of the cooling lines and fins, resulting in a lower cooling capacity, this can lead to failure of the compressor.

Condenser soiling

Dirt accumulates between the condenser and the coolant cooler over time. This blocks the air flow through the condenser and thus reduces its cooling capacity.

Leaks

In addition to soiling on the condenser surface, leaks can also reduce the cooling capacity for the gas in the system. Because of its installation position at the front of the engine compartment, depending on the use of the vehicle dead insects combined with road salt and water can lead to increased oxidation of the flat aluminium tubes, resulting in leaks. The reduction in cooling means that the pressure and compression temperature will be constantly at a higher level. This places a significant burden on the entire system.

Porous hose connections

The older the vehicle, the older the hose connections normally are too. They become porous over time and fine rubber particles become detached. As the compressed hot gas is fired from the compressor into the condenser at high pressure, this abrasion ends up in the condenser and gradually starts to clog up the tiny cooling ducts. The more the fine condenser cooling capillaries are clogged, the more of the cooling surface is lost and the condensation process is reduced. Because the hot gas is no longer completely condensed, the pressure in the air-conditioning system remains at a constantly higher pressure. This not only reduces the cooling capacity of the air-conditioning system; it also means the compressor has to work against increasingly high pressures and is thus subjected to higher (premature) wear. As the compressor has to exert more energy to work, a clogged condenser also has a negative impact on fuel consumption.