Gearbox

Gearboxes convert the torque from an engine into the traction required to drive the vehicle. By providing various transmission ratios, they enable the speed of the engine to be adapted to different driving situations.

Function

Gearboxes convert the engine torque into the wheel traction required to drive the vehicle. As internal combustion engines only operate in a narrow speed range, gearboxes transform this into the wheel speeds needed to produce the various driving speeds. They do this by providing various transmission ratios to adapt the engine speed to different driving situations. In comparison with internal combustion engines, electric motors cover a wider range of speeds and torques. For example, the full amount of torque is already available when moving off. As a basic principle, gearboxes for electric drives are designed according to the same criteria as gearboxes for internal combustion engines.

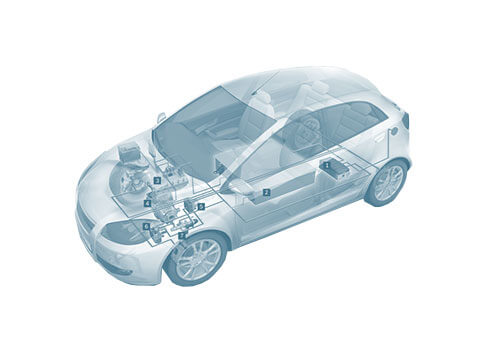

On a hybrid drive system, the internal combustion engine is combined with an electric drive machine. The way in which they are combined and integrated in the driveline is based on different concepts.

Hybrid drive: system configurations

The systems are divided into series, parallel and split-power hybrid drives depending on where the internal combustion engine, electric motor, generator and gearbox are positioned and how their tasks are divided.

Concepts

Series hybrid drive

On a series hybrid drive system, the electrical energy is generated by an internal combustion engine in combination with a generator. The vehicle is driven using electric power alone. The internal combustion engine merely powers the generator that produces the power.

This concept has the following advantages:

- The internal combustion engine can run independently of the driving status and can charge the battery even when the vehicle is stationary.

- When the internal combustion engine is off, the series hybrid drive system also enables the vehicle to be driven under electric power only, using the energy stored in the battery.

- On some drive concepts, the internal combustion engine also acts as a so-called range extender, which ensures that the vehicle does not become stranded on account of an empty battery.

Parallel hybrid drive

A parallel hybrid drive system has a clutch that mechanically connects the internal combustion engine with the wheel. In this case, the drive torque can be divided up freely between the e-motor and the internal combustion engine. The speeds are defined by the gears in the gearbox and the location of the units in the driveline. This means that the vehicle can be powered either by electric power only, using the internal combustion engine only, or by a mixture of both drive systems working simultaneously. On a parallel hybrid drive system, the power provided by the electric motor and internal combustion engine are added together to produce the overall power output. In addition to the internal combustion engine and electric motor, these types of hybrid drive systems also need one or more gearboxes and clutches.

Mixed hybrid drive

A mixed hybrid drive system, also known as a split-power hybrid drive, combines the series and parallel hybrid drive concepts. In this case, the two drive systems are connected to the drive wheels via a gearbox and the differential. The gearbox allows for different driving statuses. As with the series hybrid drive system, the internal combustion engine can thus merely power the generator and supply the electric motor with the power produced. In such cases, the vehicle is therefore driven by the electric motor alone. If the internal combustion engine is mechanically connected to the drive wheels via the gearbox, it can also drive them together with the electric motor, as is the case with the parallel hybrid drive system. It is also possible for the vehicle to be powered by the internal combustion engine alone.

All-wheel drive using the electric motor

On hybrid vehicles, all-wheel drive can be provided using an electrically powered rear axle. With this concept, a unit comprising the axle, drive shafts, electric motor and control electronics can be used instead of having a non-driven rear axle. This concept offers the advantage of all-wheel drive as the drive control system can activate the electric rear-wheel drive system as required to supplement the front-wheel drive provided by the internal combustion engine. There are also hybrid systems that provide all-wheel drive by integrating an electric axle drive system with electrified automated gearbox into the rear axle.

Dedicated hybrid transmission

Dedicated hybrid transmissions are innovative, relatively complex solutions for hybrid vehicles. In these systems, the electrical machine is integrated into the transmission, thereby improving the overall efficiency of the driveline. This integrated concept allows for cost savings when dealing with high volumes and is advantageous in terms of the installation space required.

Hybrid drive with wheel hub drive

On commercial vehicles there are hybrid concepts where internal combustion engines are combined with electric wheel hub drives.