Electric power steering system

Due to its wide-ranging advantages compared to conventional hydraulic power steering, electro-hydraulic and electric power-steering systems (“EPS”) are becoming increasingly favoured.

Function

Electro-hydraulic power-steering system

In an electro-hydraulic power-steering system (also shortened to “EHPS”), the belt-driven power-steering pump is replaced by an electro-hydraulic pump: the motor pump unit (MPU).

This MPU combines an electric motor, the associated control unit, a gear pump and a compensation tank for the fluid – all in one single housing. By using multiple sensors, the control unit calculates the required steering assistance while taking the driving speed, steering torque and steering speed into consideration before actuating the hydraulic pump accordingly.

Electric power-steering system

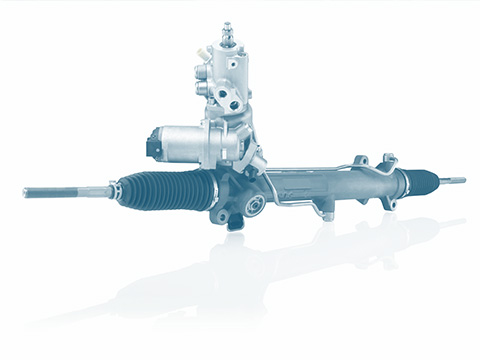

Electrically assisted steering systems, also known as electric power steering (EPS), dispense with hydraulic fluid entirely. In these systems, the steering movement is assisted by an electric motor.

Electric power steering on the steering column

So-called “column-drive” electric power steering (EPS) is a variant for which the additional steering torque is transferred to the steering shaft by means of a worm-gear transmission on the steering column. This system is used in smaller vehicles where little room is available in the engine compartment.

Due to the installation location, the requirements for the servo drive are considerably less stringent with regard to the temperature range and sealing in comparison with the conditions in the engine compartment.

Electric power steering on the steering rack

Electric power steering featuring a steering-rack/belt drive system (belt-drive EPS) features higher performance than an electric steering column. An axially parallel electric motor leading to the steering rack transmits the steering-power assistance directly to the steering rack by means of a toothed-belt drive and a recirculating-ball mechanism. This system is distinguished by the precise responsiveness of the steering and immediate feedback from the road surface.

Protection of the environment

Electro-hydraulic power-steering systems save up to 75% of the energy used by conventional power-steering systems, depending on the variant in question. Purely electric power-steering systems are even more effective and can even save up to 90% of the energy used by hydraulic power steering. By dispensing with hydraulic fluid completely, electric steering systems have a positive impact on the environment.

The reduction in energy required therefore makes a considerable contribution to reducing fuel consumption and CO2 emissions.

Value retention

With fully electric steering systems, leaks in power-steering systems are finally a thing of the past. Such electric systems are maintenance-free and enable functional tests to be conducted using a diagnosis system.

Images

Click on an image to enlarge it: