Overrunning alternator pulley

The overrunning alternator pulley is a more advanced development of the fixed pulley on the alternator. It ensures that the belt drive operates quietly and smoothly.

Function

The four-stroke principle dictates that the crankshaft in internal combustion engines is continuously accelerated and decelerated. The resulting vibrations are transmitted to the power-train drive elements. Naturally, this has an adverse effect on the noise development and the service life of the drive belt.

With its overrunning clutch, the overrunning alternator pulley cancels out these vibrations and also enables the engine rpm to be quickly reduced in the event of sudden load changes. Alternator decoupler pulleys, as a special variant of the overrunning alternator pulley, also perform a damping function.

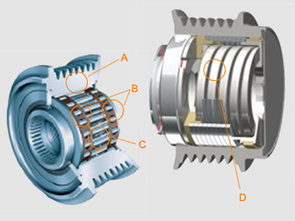

An overrunning alternator pulley essentially consists of the following components:

An overrunning alternator pulley essentially consists of the following components:

- A) Pulley

- B) Needle bearing

- C) KPinch rollers with coupling function

- Spring (only on alternator decoupler pulleys)

Due to the coupling function of the overrunning alternator pulley, the torque is only transmitted in one direction. In addition, thanks to its integrated spring/damper system, the alternator decoupler decouples the V-ribbed belt from the alternator, thereby enabling it to cancel out resonant vibrations more effectively.

Advantages of the overrunning alternator pulley at a glance:

- Avoiding vibrations and slippage throughout the entire belt drive

- Very quiet operation and low noise generation

- Optimum service life of the belt and the remaining belt-drive components

Safety

When the overrunning belt pulley is replaced, the V-ribbed belt and the tensioning pulleys and deflection rollers should also be replaced at the same time. Replacing all of these components prevents them from failing again after a short time and also prevents the associated repair on the power-train drive elements.

Value retention

Overrunning alternator pulleys are subject to ageing and wear, and they must therefore be tested and replaced at regular intervals. It is recommended to check the function of the overrunning pulley every 60,000 km and replace it every 120,000 km in case of doubt. A defect affecting the overrunning alternator pulley can lead to costly repair work or cause the engine to fail in the worst-case scenario.

Protection of the environment

Overrunning alternator pulleys made of steel have a V-ribbed belt profile. The overrunning unit on the inside is equipped with a bearing which is lubricated for its entire service life with a grease filling. Overrunning alternator pulleys primarily consist of metal and can be easily recycled after use.