Brake lines

When the driver presses the brake pedal, hydraulic pressure is generated in the master brake cylinder. So that a braking force can be produced from this, the hydraulic pressure must be transmitted to the wheel brakes with...

Function

When the driver presses the brake pedal, hydraulic pressure is generated in the master brake cylinder. So that a braking force can be produced from this, the hydraulic pressure must be transmitted to the wheel brakes with the assistance of the brake fluid. In motor vehicles, this happens via the brake lines.

Types of brake pipes

Brake lines are categorised as brake pipes or brake hoses on the basis of their design.

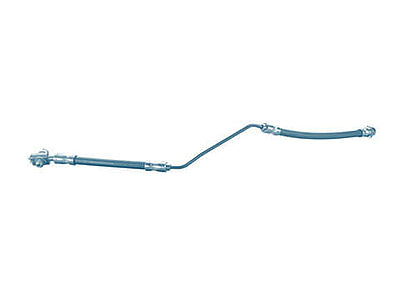

Brake pipes

Brake pipes are rigid they are made from steel. They are installed in the engine compartment, underneath the car body or in the wheel arches, i.e. anywhere where movements of brake lines are not to be expected. Depending on the application, brake pipes vary in:

- shape,

- length,

- diameter and

- connection fittings.

A plastic or zinc coating provides protection against corrosion.

Brake hoses

Brake hoses create a flexible connection between brake pipes and wheel brakes. They transmit the hydraulic pressure to the wheel cylinders and brake callipers. Brake hoses are usually made form a special inner and outer rubber with a multi-layer fabric insert in between. There are also brake hoses that are sheathed in steel braiding (braided stainless steel brake hoses).  These types of brake hose have a particularly long service life. As braided stainless steel brake hoses also expand less even at increased brake pressure, the pressure point at the brake pedal is also more exact and braking can be dosed more precisely.

These types of brake hose have a particularly long service life. As braided stainless steel brake hoses also expand less even at increased brake pressure, the pressure point at the brake pedal is also more exact and braking can be dosed more precisely.

Safety

Brake lines perform an important task in modern brake systems. To safeguard the overall function of the brake system, they must transmit the pressure generated by the driver or the brake regulating system to the wheel brakes without delay and with no losses.

If the brake lines are porous or damaged, moisture can get into the brake system from outside. This can lead to vapour locks forming in the brake fluid and impair the braking effect or, in the worst-case scenario, cause the brake to fail completely. Therefore, brake pipes and brake hoses must undergo regular inspection.

Depreciation

As the brake is a safety-relevant system in the vehicle, inspection and repair work on brake pipes and brake hoses – as on all other parts of the brake system – must only be carried out by a specialist garage.

Brake pipes and brake hoses are subject to natural wear and, in the same way, material fatigue. Spray water and salt will always cause a slight touch of corrosion on brake pipes. Similarly, brake hoses can also be damaged by external influencing factors such as ozone in the air, road salt or weasel bites, for example.

Therefore, they must be checked during every inspection and replaced if damage is discovered. Similarly, if drivers notice a decline in braking effect, they should have the brake pipes and brake hoses checked by a garage.

Downloads

Here you can find all available downloads for the topic "Brake lines":

All file downloads: