Oxygen sensor

The oxygen sensor is an instrument for managing the exhaust emissions of petrol, diesel and gas engines. It is an oxygen concentration sensor which measures the residual oxygen content of the exhaust gases and...

Function

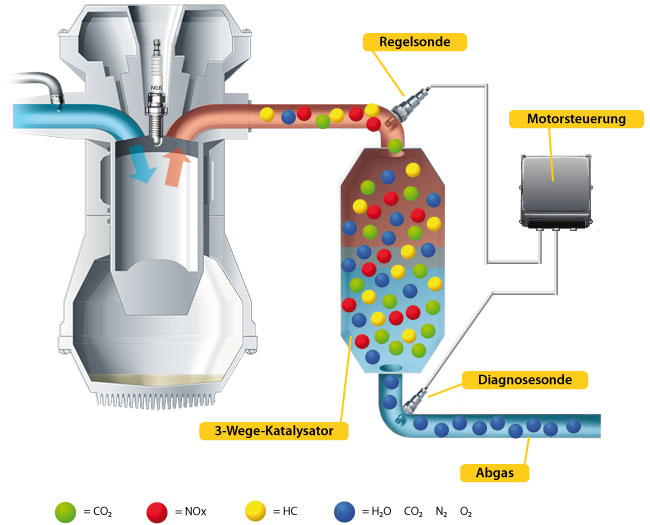

The oxygen sensor is an instrument for managing the exhaust emissions of petrol, diesel and gas engines. It is an oxygen concentration sensor which measures the residual oxygen content of the exhaust gases and then transmits a signal to the engine management system in the form of an electric voltage. The oxygen sensor voltage allows the control unit to detect whether the mixture is too lean or rich. The control unit reduces the quantity of fuel in the A/F ratio if it is too rich, and increases it if it is too lean.

The value measured by the oxygen sensor allows the control unit to adjust the amount of fuel injected to attain an optimum mixture. This creates ideal conditions for treatment of the exhaust gases in the catalytic converter. This also takes account of the engine load.

The value measured by the oxygen sensor allows the control unit to adjust the amount of fuel injected to attain an optimum mixture. This creates ideal conditions for treatment of the exhaust gases in the catalytic converter. This also takes account of the engine load.

There may also be a second oxygen sensor, the diagnostic sensor (downstream of the catalytic converter). This detects whether the control sensor (upstream of the CAT) is functioning to optimum effect. The control unit can then calculate how to compensate for this.

Types of oxygen sensors

Today there are basically two different types of sensor:

Binary sensor

Today there are basically two different types of sensor: the binary and the wideband sensor. When at operating temperature (from 350 °C), the binary sensor generates a change in electric voltage depending on the oxygen level in the exhaust. It compares the residual oxygen content in the exhaust with the oxygen level of the ambient air and identifies the transition from a rich mixture (lack of air) to a lean mixture (excess air) and vice versa.

Wideband sensor

The wideband sensor is extremely accurate when measuring both a rich and lean air/fuel ratio. It has a greater measuring range and is also suitable for use in diesel and gas engines.

The wideband sensor is extremely accurate when measuring both a rich and lean air/fuel ratio. It has a greater measuring range and is also suitable for use in diesel and gas engines.

Nowadays heated oxygen sensors are used to ensure the oxygen sensors attain operating temperature more quickly and can thus intervene earlier in the emission control process. Heated HEGO sensors no longer need to be installed so close to the engine.

Structure of the oxygen sensor

Finger-type sensor

The core of the finger-type sensor consists of a finger-shaped ceramic element. It is heated by a heater incorporated in the sensor as control is possible only at a minimum operating temperature of 350 °C. The exhaust gases flow over the electrode side of the sensor element, while the other is in contact with the outside air. The outside air here acts as a reference for measurement of the residual oxygen content. To protect the sensor element from combustion residues and condensate in the exhaust gas, the sensor housing is fitted with a protection tube at the exhaust gas end.

Planar sensor

The planar oxygen sensor is manufactured using thick-film-technology. The shape of the sensor element resembles an elongated plate. Both the measuring cell and the heating element are integrated in this plate, so allowing the sensor to attain its operating state more quickly. Here too suitable protection tubes are used to protect the sensor element from combustion residues and condensate in the exhaust.

Environmental protection

Exhaust emissions standards and limit values are becoming increasingly stringent. Oxygen sensors became indispensable long ago to ensure the efficient reduction of emissions. More recent vehicles usually feature a configuration with two oxygen sensors described above. Here the two sensors monitor each other and so regulate functioning of the catalytic converter. This is the only way to further reduce exhaust emissions in coming years.

Development of the planar universal exhaust gas oxygen sensor has made another important contribution to ensuring vehicle engines are more environmentally friendly. They reach their operating temperature in less than five seconds and so guarantee maximum control quality even in the emission-intensive cold start phase.

Oxygen sensors are subject to extreme loads. Perfect functioning of the oxygen sensor is necessary if your engine is to be reliable - thus ensuring:

- Low fuel consumption

- Low pollutant emissions

- Compliant exhaust emission values

When expressed in figures, this represents a cut in fuel consumption by as much as 15 percent compared with older or defective oxygen sensors.

If you replace the oxygen sensor in good time, you can also avoid costly damage to your CAT and improve vehicle performance.