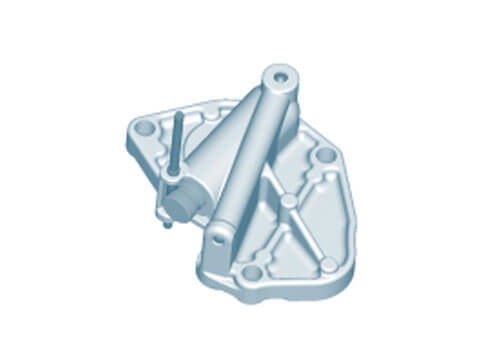

Electronically switchable engine mount

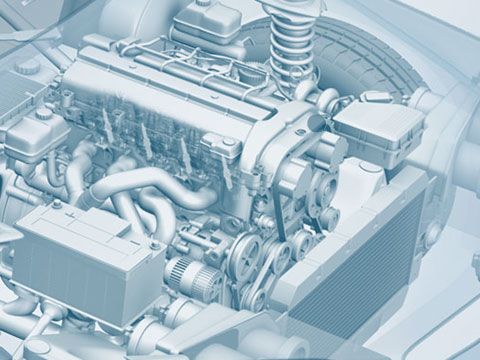

In vehicles, the engine mounts create a connection between the engine and the body. In contrast to conventional engine mounts, electronically switchable engine mounts can be actively controlled, and can thereby adapt to different situations.

Function

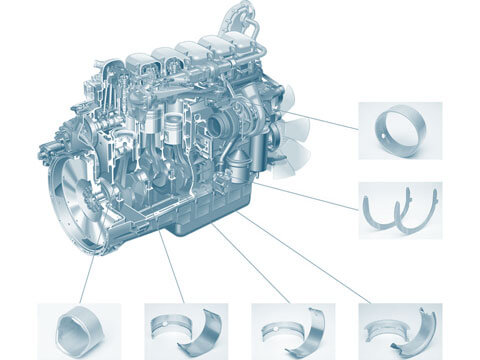

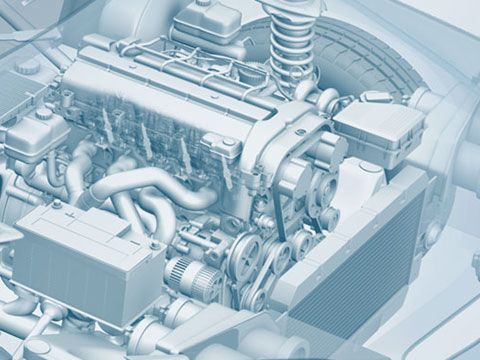

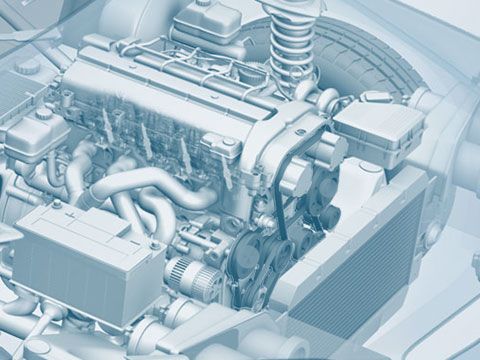

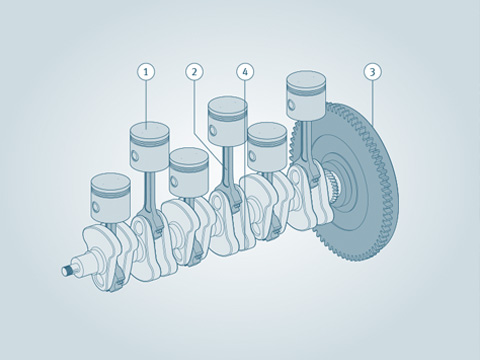

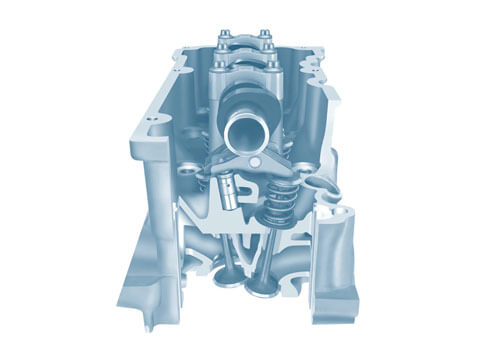

A car engine never vibrates evenly: when the vehicle is moving, different vibrations and noises are generated compared to when the engine is idling. This imposes complex requirements on the engine mount. Conventional engine mounts are simply a compromise between ideal damping during idling and ideal damping during average driving situations. At the same time, the requirements placed on engine mounts are becoming ever more demanding. Modern engines are becoming more and more compact, often have fewer cylinders and less capacity, increasingly frequently have turbocharging, direct injection and new technologies such as cylinder deactivation. They are designed with the aim of saving fuel, having state-of-the-art driving dynamics and providing the highest level of comfort in the passenger compartment. Electronically switchable engine mounts increase the options provided by conventional, hydraulic engine mounts, can be actively controlled and can adapt to different situations. Depending on the engine excitation frequency, the engine mount dampens on a purely hydraulic, passive or active basis. The isolation characteristic is calculated by the control unit and implemented by the actuator so that there are no critical vibrations on the vehicle body.

Functioning

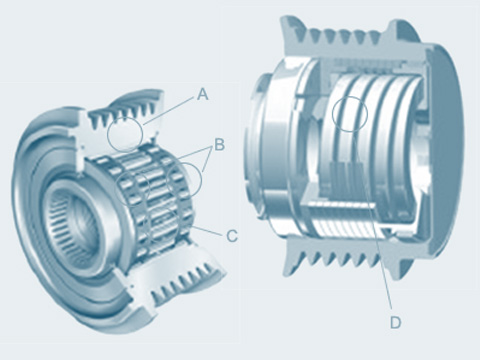

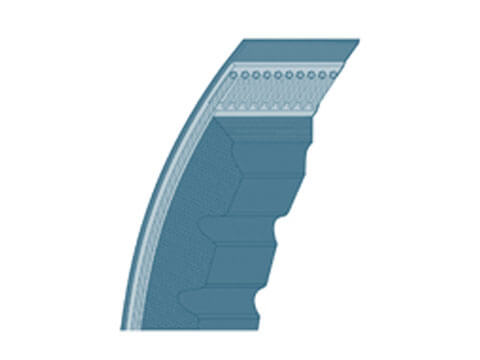

A: In the comfort position, the valve (2) is open and, as a result, permits the motion of the air suspension (3). The result is a soft range of spring (1). B:In the driving dynamic position, the valve (2) is closed and, as a result, permits the motion of the hydraulic area (4). The result is a dynamically hard range of spring (1). The advantages of electronically switchable engine mounts: • They react intelligently to the applicable requirements. • They improve vibrational comfort. • They improve high-frequency behaviour. • The set-up of the mounts as regards rigidity, damping positions and idling behaviour is customisable. • They enable maximum comfort even with the toughest requirements.

Safety

Engine mounts must ensure a permanent connection between the engine and body. Original components guarantee faultless function. Faulty engine mounts can cause vibration and negatively influence the handling of the vehicle. This is why faulty engine mounts should be replaced immediately.

Value retention

Faulty engine mounts often cause vibration or noises. In this case, an automotive workshop should be contacted immediately. If the engine mounts are faulty, unwanted vibration can be transferred to other components and cause damage there – and the repair of these can lead to high costs. In the worst case scenario, the mount can break and the engine block can move around uncontrolled in the engine compartment. This is why faulty engine mounts should be replaced as quickly as possible.